The HVAMC was one of the early adopters of the Desktop Metal Studio system which prints a variety of metals using a process called Bound Metal Deposition (BMD). A good description of BMD is available here. We have been interested in printing metal for a while, but the process used in most metal printers, laser sintering or laser melting, was too expensive to both purchase and operate for what we thought we could do with it. One of the principal missions of the HVAMC is to provide state-of-the-art 3D printing and expertise to regional manufacturers and laser sintering is too expensive to generally be a viable solution for the companies we work with. To summarize the advantages of BMD over laser sintering:

1) BMD is between 5X and 10X lower cost than laser sintering to make a part of similar quality.

2) BMD is considerably more flexible in that materials can be changed out in about an hour. We currently run 316L and 17-4PH stainless steels and copper. We can, if needed, also print inconel 625, H13 tool steel and Titanium64.

3) There are fewer hazards associated with BMD because it does not require working with very finely divided metal powder.

4) The standard sintering process used in BMD leads to more predictable material properties.

There are some disadvantages in that BMD is a multi-step process and has more design restrictions than laser sintering, but the dramatically lower cost makes it a useful solution for both prototyping and final part production.

Most Recent Batch of JBT Parts

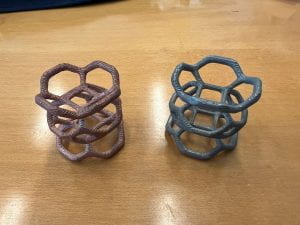

I would like to describe one very nice example of a final use part that we have been printing for several years now for JBT in Kingston, NY. I would like to thank JBT for allowing me to write about this. They have been a great company to work with because they have been willing to explore using 3D printed parts as solutions for interesting manufacturing challenges. The parts we have been printing for them in 17-4PH stainless steel are shown to the right. The part is a Roller Guide Saw Nozzle Block and is part of JBT’s Adaptive 3D Portioning System, a large and very sophisticated system for the rapid processing of poultry, meat and seafood. The system simultaneously uses both water jet and mechanical cutting systems. The part is small and complex because it needed to serve several different purposes in a limited space. The installed part is shown below.

Installed Roller Guide

In a number respects, this is an ideal case for a final-use 3D printed part, metal or polymer. Key characteristics include:

- Low volume. With our Desktop Metal system, we can handle making 20-30 of these parts in a reasonable amount of time, say 2-3 weeks. Of course this can be scaled and the relatively low cost of BMD might make that worthwhile.

- High complexity. I’ll leave it to experts in machining to determine where this part could be made by CNC, but I suspect that JBT would have made it that way if they could have.

- Small size. Of course larger objects are 3D printed all the time, but I believe that 3D printing is at its greatest advantage relative to machining with smaller parts. We charge for 3D printing by the amount of material used so a smaller 3D printed part is relatively less expensive than a smaller machined part. The complexity of the part is not really a factor so how a designer or engineer thinks about the design and cost of an additively made part is significantly different then designing or pricing for subtractive fabrication.

I’d like to thank JBT again for partnering with us and letting me tell this story. I know there was a lot of hype that suggested that a lot or even the majority of manufacturing would be done using 3D printing. That is not likely to ever be the case, but it is worth while for designers and engineers in the manufacturing world to keep track of what’s possible because you never know when a solution to a sticky problem will be a 3D printer. If anyone ever has any questions about whether additive manufacturing can be a solution to a particular problem, please do not hesitate to contact the HVAMC.

Keep On Printing!

Dan